Precision Alignment Services

Rigid Industrial’s precision alignment services have earned the trust of facility managers throughout industrial sectors by applying proven precision measurement techniques to rotating equipment with final results seen in the reduction of forced downtimes and an increase of cost-saving benefits.

By combining precise coordinate measurement tooling with our expertise, we ensure your rotating components are properly aligned to OEM specifications providing your equipment the ability to run at its maximum capability; shrinking unexpected downtime, reducing excessive wear issues, and increasing production quality. Our vast experience allows us to provide highly accurate measurements and dependable service to industrial facilities, including (but not limited to):

- Aluminum, Plastic & Steel Manufacturing

- Pulp & Paper

- Chemical Processing

- Construction

- Cement Manufacturing

- Petroleum Refining

- Pharmaceutical Production

- Power & Energy

Rigid’s alignment technicians are knowledgeable and efficient, using industry-leading, time-tested tools to provide the accuracy and innovation that helps our clients improve processes, maintain warranty validity and operate more profitably.

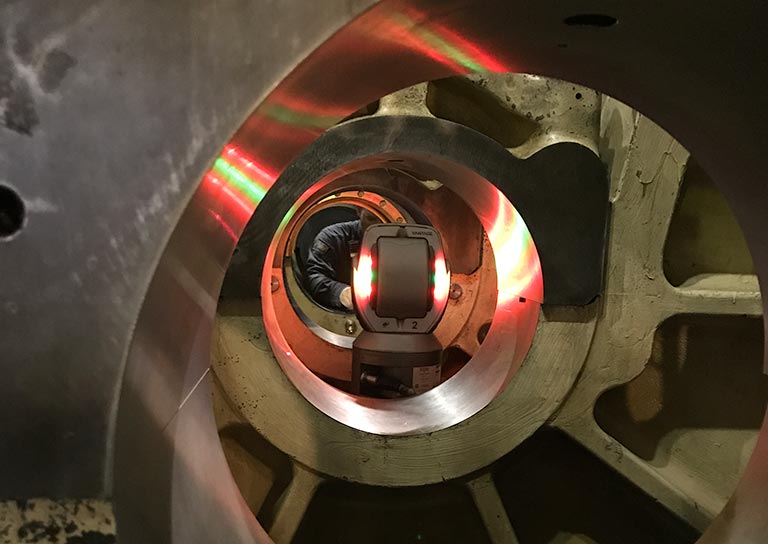

Laser Alignment

As the industry standard for accurate measurements with multiple types of equipment and machinery, Rigid’s state-of-the-art laser alignment services help improve overall equipment performance by solving problems caused by misalignment. Utilizing our laser trackers to obtain precise measurements, we can quickly ascertain highly-accurate coordinate readings to achieve nearly flawless alignment results with the tightest possible tolerances. Our capabilities typically include 0.0015” point-to-point accuracy.

Whether your components are undergoing initial alignment at installation or they need ongoing alignment during maintenance outages, our alignment teams are committed to providing professional services with final reporting at the end of each project.

Benefits of Laser Alignment

Misalignment can be caused by several factors, including skimping on initial alignment needs, utilizing inexperienced alignment companies, poor foundations, excessive vibration , warped machine bodies, cyclical fatigue or other forces, causing prematurely worn bearings, couplings and belts, thermal growth and more. Precision alignment services can identify and correct these issues simply by ensuring your equipment is properly aligned. Other benefits of our laser alignment services include:

- Reduced maintenance costs

- Increased productivity

- Higher quality output

- Decreased downtime

- Less overall waste

- Longer-lasting machine parts

- Minimized opportunity for errors

- Limited excess material costs

Rigid’s precision alignment services can provide the right solution for your industrial facility. Call today to discover how we can help your operations run more smoothly and profitably.

Schedule A Visit

Our industrial alignment teams serve clients across the USA and our services are fully customized to meet the unique needs of each facility. Rigid Industrial believes in cultivating long-term relationships with our clients and providing the best possible service to support your facility’s success.

Please feel free to contact Jason Drake at 903.650.0541 or jasondrake@rigidindustrial.com to discuss your alignment needs, request an estimate or schedule a walkthrough for your next alignment project.